Pavan GBS Group Made European Brand Flour Milling Roller Mills Used ROLLERMILL SYNTH Rollermills Belt Timing Rollermills Admin Edit

18 pieces of genuine Italy GBS Brand Flour Milling Rollermills, Wheat milling machines for hard/soft wheat milling process. FOB Selling Price in USD8800/unit. Excellent Running Condition, We bought the wheat milling roller mills in year of 2019 and the machines were shut down in year of 2012, all 18 pcs Rollermills are 300/1000 and total milling capacity is 350Tons per 24hrs.

The Synthesis Rollermill encloses the quintessence of milling technology and of the knowledge developed by Golfetto Sangati in over 80 years of experience in the sector. All models can be supplied with rolls of 250 or 300 mm in diameter.

A ROLLERMILL THAT GOES BEYOND YOUR IMMAGINATION

The most popular, highperformance machine on the market, Synthesis comes in 2, 4 and 8 rolls versions. Simple to run and versatile enough to cope with the specific milling requirements of whatever country it operates in.

Excellent distribution of the product on the feeder rolls

The large chamber below the bellshaped hopper allows the material to pass through more easily.

Efficient, silent grinding

The product is fed through to the grinding cylinders with micrometric precision, and spread right across the breadth of the machine.

Details that matter

Two solid cast-iron bases, linked by sturdy carbon steel beams to guarantee perfect stability and thus reduce vibrations to zero.

Simple mechanics

A single double-sided Poly V belt rotates the grinding cylinders. During disassembly of the grinding cylinders, the kinematic mechanisms that control the engagement/disengagement of the rolls remain integral with the machine by virtue of an exclusive mechanical geometry. This means there is no need to recalibrate the grinding components when they are replaced.

Simplified maintenance

The entire power supply unit of the power train components is mounted on ball-bearing slides, so it can be extracted to access the feeding chamber for cleaning operations. The front block of the machine snaps quickly onto the internal structure and can be raised in order to give operators immediate access to the grinding cylinders and the feeder area.

Checking on-the-go

The electric control unit, together with the frequency converters, is housed in containers placed on the front of the machine under the inspection hatch, allowing for safe, easy access even when the machine is in operation.

Direct pick-up

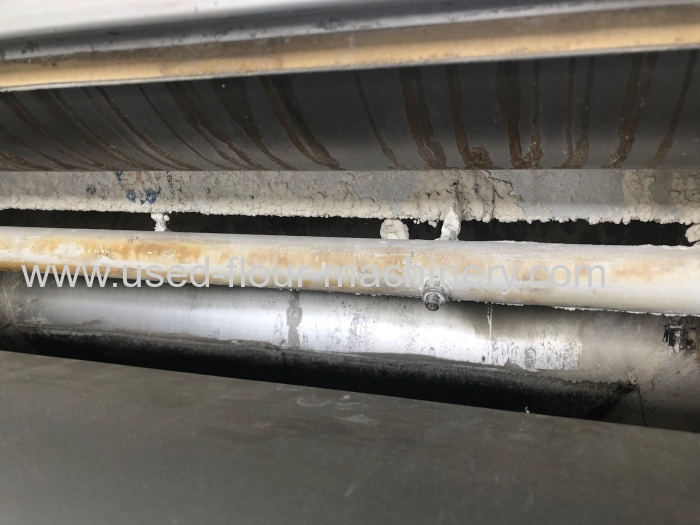

The pneumatic suction tube is positioned right inside the machine, with the rollermill resting directly on the surface.

Related Links

Category: Golfetto Roller Mills

Related Category: Ocrim Roller Mills Buhler China Roller Mill Buhler Roller Mills